The Centers for Medicare and Medicaid Services will be issuing a new rule that would establish a value-based purchasing program for acute care hospitals paid under the Medicare Inpatient Prospective Payment System for inpatient services furnished to Medicare Benificiaries. The new program required by the Patient Protection and Affordable Care Act of 2010, would provide value-based incentive payments to hospitals beginning in FY 2013, based on their achievement of or improvement across a set of clinical quality and patient experience measures.

One of the survey questions under patient experiences is;

“During this hospital stay, how often was the area around your room quiet at night?”

Noise Monitors, placed on the wall, can provide instant visual feedback if the noise levels get too high.

SoundEar II® has been specifically developed for use in hospitals and is approved in accordance with IEC 60601-1 (medical electrical equipment)

SoundEar II® has been specifically developed for use in hospitals and is approved in accordance with IEC 60601-1 (medical electrical equipment)

Find out more about SoundEar Products, Click Here

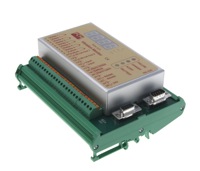

These new monitors have a PC interface for setting up the unit and displaying the results of the measurements. The programmed data is stored within the unit to enable the monitor to operate independently of the PC and retained in the case of a power failure. The DSP allows for the choice of many low pass and high pass filters as well as true RMS, Peak or Peak-to-Peak measurements. In addition, there are many built-in test functions and voltage references for checking out new test set-ups as well as system failure indicators and relays. The built-in relays are used to interface with PLC’s and other instrumentation and are triggered upon user defined threshold levels. In addition, there are electrical outputs for conditioned and unconditioned AC signals for additional spectrum analysis or waveform storage. These monitors are ideal for real time detection and control of vibration and acoustic events.

These new monitors have a PC interface for setting up the unit and displaying the results of the measurements. The programmed data is stored within the unit to enable the monitor to operate independently of the PC and retained in the case of a power failure. The DSP allows for the choice of many low pass and high pass filters as well as true RMS, Peak or Peak-to-Peak measurements. In addition, there are many built-in test functions and voltage references for checking out new test set-ups as well as system failure indicators and relays. The built-in relays are used to interface with PLC’s and other instrumentation and are triggered upon user defined threshold levels. In addition, there are electrical outputs for conditioned and unconditioned AC signals for additional spectrum analysis or waveform storage. These monitors are ideal for real time detection and control of vibration and acoustic events.

PCH Engineering has also developed a range of monitors for multichannel measurements using FFT analysis on an incoming vibration or acoustic signal. This FFT analysis can be defined by the end user to meet the particular needs of the application. The sampled time block is chosen to reflect the bandwidth of interest. Alarm limits can be set on particular bands of interest within the FFT and are user selectable. Several frequency bands can be chosen and defined by the upper and lower frequency. The resultant FFT calculations, updated for every time block, are displayed with the alarm bands highlighted while the PC is attached to the monitor for setup and testing.

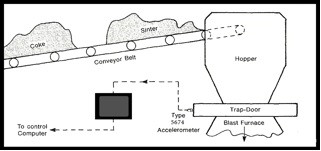

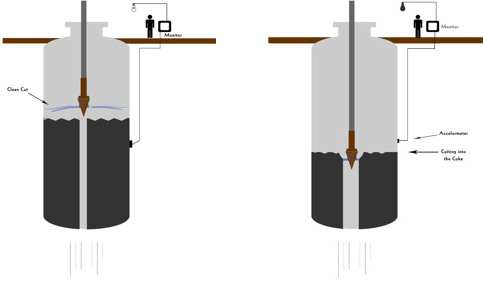

PCH Engineering has also developed a range of monitors for multichannel measurements using FFT analysis on an incoming vibration or acoustic signal. This FFT analysis can be defined by the end user to meet the particular needs of the application. The sampled time block is chosen to reflect the bandwidth of interest. Alarm limits can be set on particular bands of interest within the FFT and are user selectable. Several frequency bands can be chosen and defined by the upper and lower frequency. The resultant FFT calculations, updated for every time block, are displayed with the alarm bands highlighted while the PC is attached to the monitor for setup and testing. Another application was found at an oil refinery. After refinement of the oil into various gasoline products, the left over sludge is pumped into very large vessels or drums. Once there, the sludge is pressurized and heated until most hydrocarbons are extracted. The material that is left over is called Coke and has the consistency of charcoal. This leftover coke has to be flushed out of the drums with high pressure water jets so that the next batch of sludge can be pumped in. This is a twenty-four hour seven days a week operation and the faster the coke can be flushed out the faster the next batch can be processed. When the operators flush out the coke with the high pressure jets, there is a noticeable noise when the jets cut through the coke and is hitting the side of the drum. This is referred to as a clean cut and the sound is very much like the sound the spray of a garden hose on an empty metal trash can. When the jets are into the coke, or cutting the material, there is a noticeable quieting of the sound. It is important for the operators to know when there is a “clean cut” so that they do not waste time here and can maneuver the jets to a lower level to cut into the material. The operators should spend as much time as they can cutting the coke and less time at the clean cutting positions. An accelerometer mounted in an ideal location on the side of the drum is able to pick up this cutting noise when the jets are hitting the side of the drum. The monitor is able to close relays to illuminate lights to let the operator know when there is a clean cut. The light turns off when the jets are cutting into the coke material.

Another application was found at an oil refinery. After refinement of the oil into various gasoline products, the left over sludge is pumped into very large vessels or drums. Once there, the sludge is pressurized and heated until most hydrocarbons are extracted. The material that is left over is called Coke and has the consistency of charcoal. This leftover coke has to be flushed out of the drums with high pressure water jets so that the next batch of sludge can be pumped in. This is a twenty-four hour seven days a week operation and the faster the coke can be flushed out the faster the next batch can be processed. When the operators flush out the coke with the high pressure jets, there is a noticeable noise when the jets cut through the coke and is hitting the side of the drum. This is referred to as a clean cut and the sound is very much like the sound the spray of a garden hose on an empty metal trash can. When the jets are into the coke, or cutting the material, there is a noticeable quieting of the sound. It is important for the operators to know when there is a “clean cut” so that they do not waste time here and can maneuver the jets to a lower level to cut into the material. The operators should spend as much time as they can cutting the coke and less time at the clean cutting positions. An accelerometer mounted in an ideal location on the side of the drum is able to pick up this cutting noise when the jets are hitting the side of the drum. The monitor is able to close relays to illuminate lights to let the operator know when there is a clean cut. The light turns off when the jets are cutting into the coke material. These low cost, autonomous monitors are very useful in situations where an acoustic or vibration event needs to be detected and acted upon to save time and expense. More information can be obtained at

These low cost, autonomous monitors are very useful in situations where an acoustic or vibration event needs to be detected and acted upon to save time and expense. More information can be obtained at